A masterpiece in stone

Renewing the wall coverings at the Urft dam with PCI construction products

A masterpiece in stone

Renewing the wall coverings at the Urft dam with PCI construction products

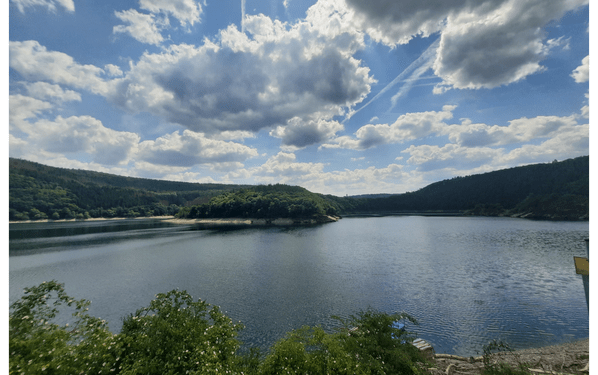

Built in the early 1900s, the Urft dam is not only the oldest dam in the Eifel (a low mountain range in Germany), but also a popular tourist destination in the Eifel National Park which was established in 2004. As the weather had taken its toll on the wall coverings, they had to be renewed. The solid greywacke slabs which were newly laid for this purpose required an extremely stable substrate. PCI supplied the appropriate products including installation recommendations and advice.

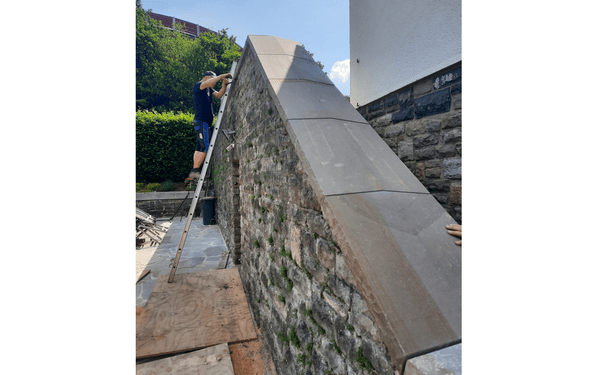

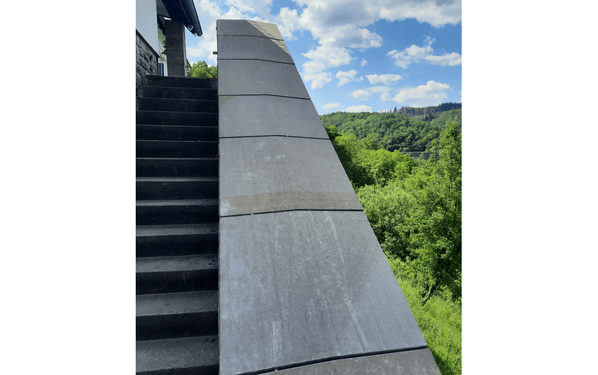

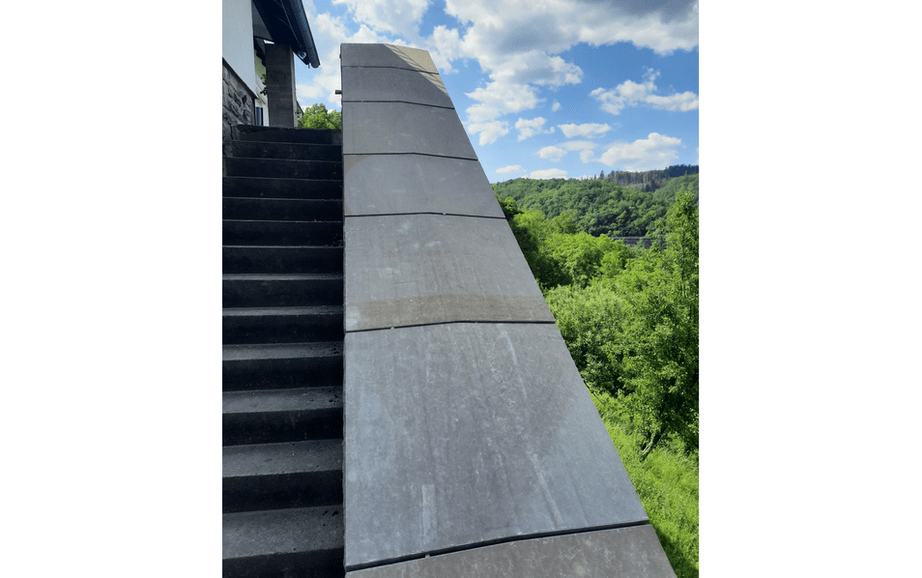

The impressive Urft dam, an imposing structure of historical significance, rises up amidst the picturesque backdrop of the Northern Eifel. The dam which was built between 1900 and 1905 stretches over 226 meters and rises 58.5 meters into the air. Its main task is to dam up the river Urft and form the Urft reservoir. As part of a necessary construction project, a total of 53 meters of wall coverings made of robust greywacke natural stone were laid here - in a privately used area that is not accessible to the public. Each of these coverings is custom-made and weighs an impressive 60 kilograms. Such massive slabs with a thickness of 7 to 10 cm serve as weather protection for the rear-ventilated exterior cladding. The challenge was to adequately prepare the substrate which consisted of a combination of concrete, quarry stone masonry and pure quarry stone in order to install the wall coverings safely and permanently.

High demands on the laying material

The Urft dam lies within the area of responsibility of the Eifel-Rur Water Association. The association commissioned Geschwister Balter Bauunternehmung GmbH from Losheim in the Eifel region with the renovation project. The family business contacted the PCI experts in advance as the task was not only technically demanding, but also placed high demands on the material used. "The solid stone slabs require a substrate that guarantees 100 percent stability and prevents them from sinking in. The high quality of PCI products is ideal for this," emphasizes Achim Dimmer from Geschwister Balter Bauunternehmung GmbH. "When renewing the wall, we implemented the construction recommendation provided by the PCI application technicians and were completely satisfied with the result."

Solid base for optimum adhesion

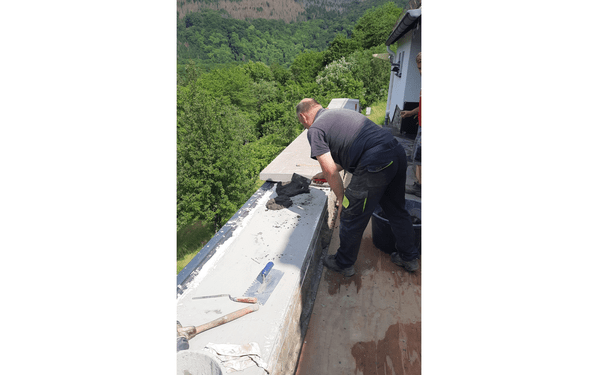

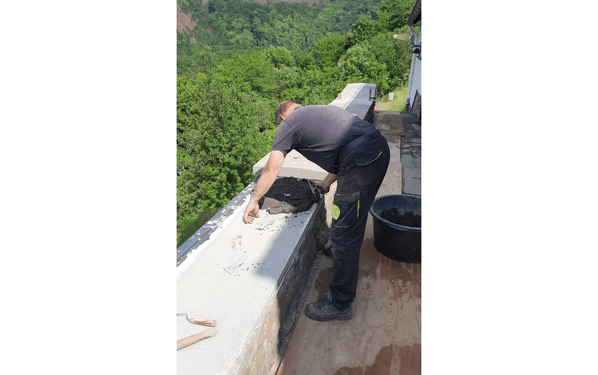

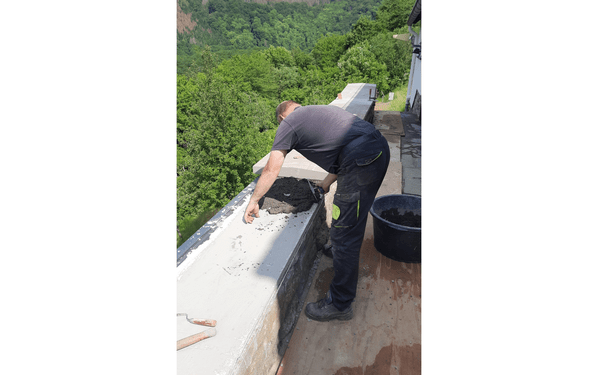

The renovation was carried out with the utmost care and expertise. The first step was the comprehensive preparation of the substrate. "The base had to be in a clean, stable and load-bearing condition, at the same time open-pored and absorbent as well as sufficiently rough to ensure the necessary adhesion of the wall coverings," explains PCI specialist consultant Sascha Wilden. To do this, layers that would impair adhesion were removed using various measures such as chiseling and grinding. This enabled an optimal adhesion and created a suitable basis for attaching the greywacke slabs.

Step-by-step renewal

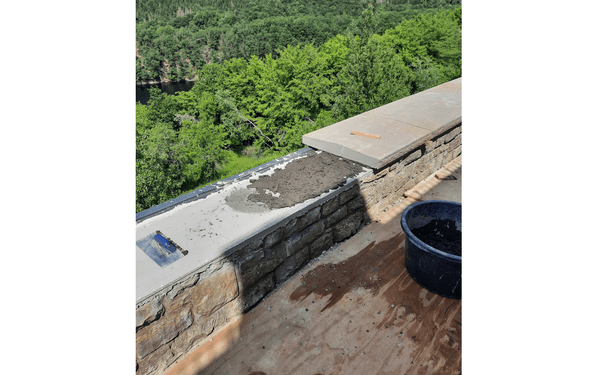

To ensure an even level, the craftspeople applied the cementitious mortar bonding agent PCI Repahaft to the prepared substrate. This was followed by the application of PCI Novoment M3 Plus to achieve a layer thickness of around 40 mm. The ready-mixed mortar is ideal for this as it even allows layer thicknesses of up to 80 mm. After a drying time of three days, the conditions were given to safely install the wall coverings.

The subsequent laying of the new, solid greywacke wall coverings was carried out in several stages. The craftspeople applied a contact layer of PCI Carrament Grey and covered it with PCI Carraroc in the desired layer thickness of maximum 40 mm. Both materials offer optimum results for laying large-format tiles. PCI Carraroc is perfect for setting natural stone and fixing natural stone walls and kerbstones. The mortar is characterized by its flexibility, high stability and permanent resistance to weather conditions which is of crucial importance at the Urft dam site.

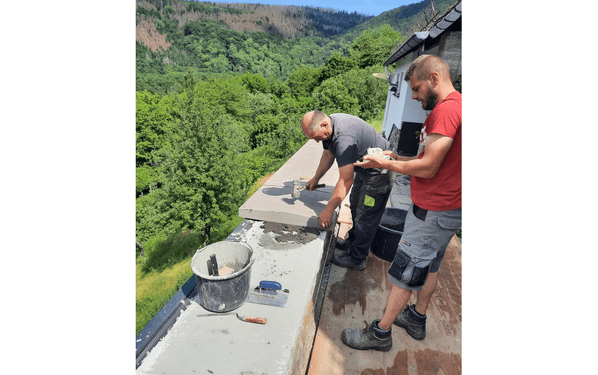

Secure anchoring in the mortar bed

The coverings were then embedded in the mortar bed which was still damp and additionally anchored to the substrate using stainless steel pins and brackets. This allowed the craftspeople to ensure that the slabs would not shift. "Especially in places where the wall slopes downwards it was necessary to use strong dowels to prevent the solid stones from sliding downwards," says Sascha Wilden.

Finally, the craftspeople sealed the butt joints of the wall coverings with PCI Carraferm, a silicone sealant for natural stone. PCI Carraferm is elastic, resistant to weather conditions and ideally suited for closing connection and expansion joints without staining. This measure therefore not only enhanced the aesthetics but above all increased the durability and weather resistance of the construction.

High-quality materials, timeless heritage

The renovation of the wall coverings at the Urft dam is an impressive example of how the combination of expert craftsmanship and high-quality building products from PCI can help to not only preserve historic buildings, but also safeguard them for future generations and maintain their aesthetics and functionality.

The impressive Urft dam, an imposing structure of historical significance, rises up amidst the picturesque backdrop of the Northern Eifel. The dam which was built between 1900 and 1905 stretches over 226 meters and rises 58.5 meters into the air. Its main task is to dam up the river Urft and form the Urft reservoir. As part of a necessary construction project, a total of 53 meters of wall coverings made of robust greywacke natural stone were laid here - in a privately used area that is not accessible to the public. Each of these coverings is custom-made and weighs an impressive 60 kilograms. Such massive slabs with a thickness of 7 to 10 cm serve as weather protection for the rear-ventilated exterior cladding. The challenge was to adequately prepare the substrate which consisted of a combination of concrete, quarry stone masonry and pure quarry stone in order to install the wall coverings safely and permanently.

High demands on the laying material

The Urft dam lies within the area of responsibility of the Eifel-Rur Water Association. The association commissioned Geschwister Balter Bauunternehmung GmbH from Losheim in the Eifel region with the renovation project. The family business contacted the PCI experts in advance as the task was not only technically demanding, but also placed high demands on the material used. "The solid stone slabs require a substrate that guarantees 100 percent stability and prevents them from sinking in. The high quality of PCI products is ideal for this," emphasizes Achim Dimmer from Geschwister Balter Bauunternehmung GmbH. "When renewing the wall, we implemented the construction recommendation provided by the PCI application technicians and were completely satisfied with the result."

Solid base for optimum adhesion

The renovation was carried out with the utmost care and expertise. The first step was the comprehensive preparation of the substrate. "The base had to be in a clean, stable and load-bearing condition, at the same time open-pored and absorbent as well as sufficiently rough to ensure the necessary adhesion of the wall coverings," explains PCI specialist consultant Sascha Wilden. To do this, layers that would impair adhesion were removed using various measures such as chiseling and grinding. This enabled an optimal adhesion and created a suitable basis for attaching the greywacke slabs.

Step-by-step renewal

To ensure an even level, the craftspeople applied the cementitious mortar bonding agent PCI Repahaft to the prepared substrate. This was followed by the application of PCI Novoment M3 Plus to achieve a layer thickness of around 40 mm. The ready-mixed mortar is ideal for this as it even allows layer thicknesses of up to 80 mm. After a drying time of three days, the conditions were given to safely install the wall coverings.

The subsequent laying of the new, solid greywacke wall coverings was carried out in several stages. The craftspeople applied a contact layer of PCI Carrament Grey and covered it with PCI Carraroc in the desired layer thickness of maximum 40 mm. Both materials offer optimum results for laying large-format tiles. PCI Carraroc is perfect for setting natural stone and fixing natural stone walls and kerbstones. The mortar is characterized by its flexibility, high stability and permanent resistance to weather conditions which is of crucial importance at the Urft dam site.

Secure anchoring in the mortar bed

The coverings were then embedded in the mortar bed which was still damp and additionally anchored to the substrate using stainless steel pins and brackets. This allowed the craftspeople to ensure that the slabs would not shift. "Especially in places where the wall slopes downwards it was necessary to use strong dowels to prevent the solid stones from sliding downwards," says Sascha Wilden.

Finally, the craftspeople sealed the butt joints of the wall coverings with PCI Carraferm, a silicone sealant for natural stone. PCI Carraferm is elastic, resistant to weather conditions and ideally suited for closing connection and expansion joints without staining. This measure therefore not only enhanced the aesthetics but above all increased the durability and weather resistance of the construction.

High-quality materials, timeless heritage

The renovation of the wall coverings at the Urft dam is an impressive example of how the combination of expert craftsmanship and high-quality building products from PCI can help to not only preserve historic buildings, but also safeguard them for future generations and maintain their aesthetics and functionality.

Date

10.06.2024

Task

Renewing the wall coverings with PCI construction products

City

Schleiden

Completion

2023

Products used

PCI Carraroc

Specialist advice

Sascha Wilden & Uwe Schellscheidt

Company

Geschwister Balter Bauunternehmung GmbH from Losheim

Your contact for inquiries:

PCI Augsburg GmbH

Piccardstraße 11, 86159 Augsburg

Telefon: +49 821 5901-0

E-Mail: pci-info@pci-group.eu

www.pci-augsburg.de